An Internal Combustion Engine that just might be the final statement of authority in a long line of engineering artistry from Ferrari, has been perfectly recreated at ¼ of the real size by the world’s leading makers of fine models.

|

|

|

|

|

|

|

|

Friday the 17th of February 2023, Bristol, UK

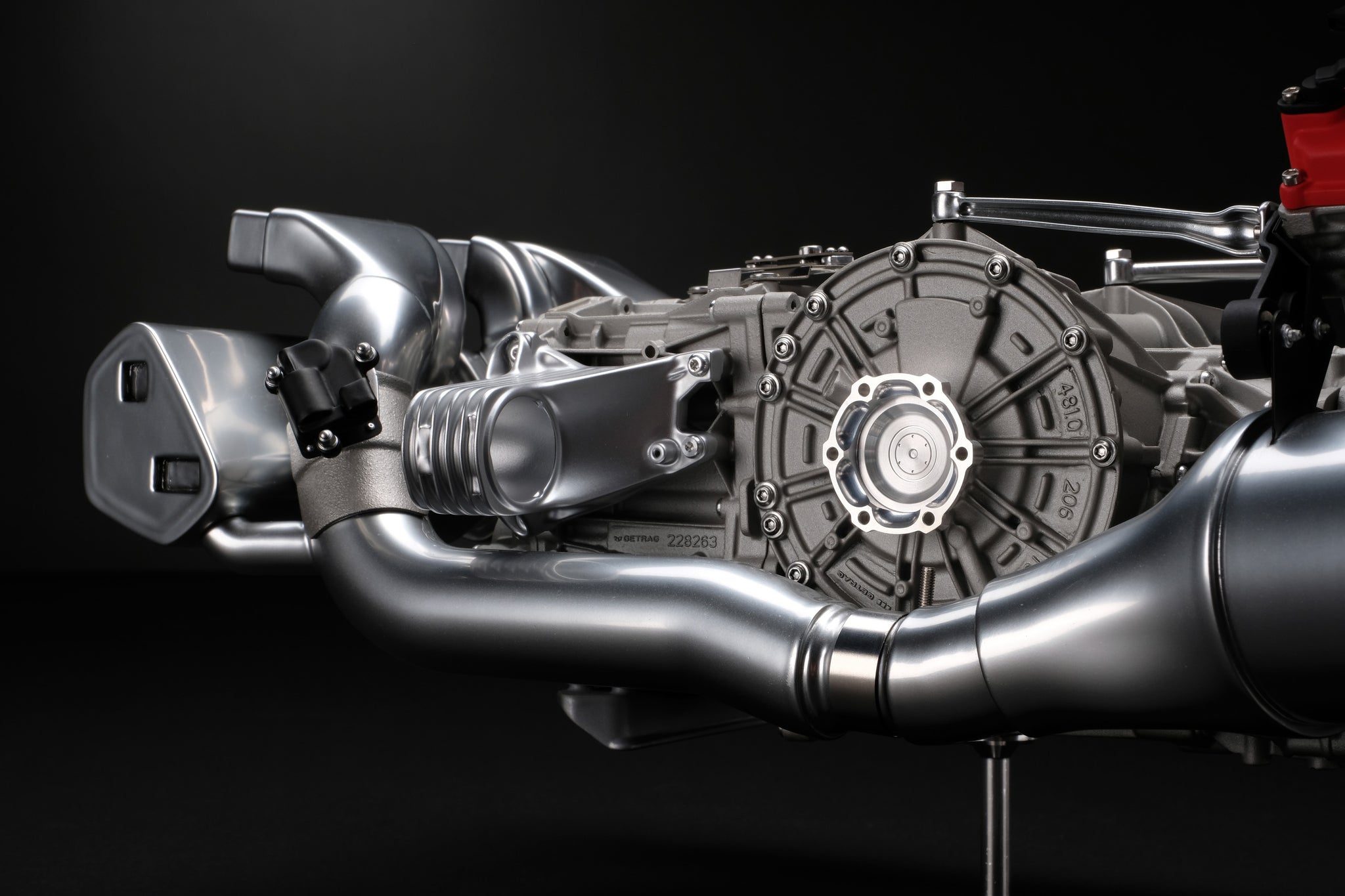

The world’s leading model makers at Amalgam Collection today unveiled the first completed scale replica of the phenomenal Ferrari Daytona SP3 Engine and Gearbox. The F140HC engine and its accompanying seven-speed gearbox have been perfectly replicated at 1:4 scale, exhibiting every perfectly engineered detail of the 6496cc V12 power unit at the heart of the Daytona SP3. Like Amalgam’s 1:8 scale model of this new Icona Series car, the engine and gearbox replica is also limited to an edition of 599 pieces, and is a celebration of the most powerful internal combustion engine that Ferrari has ever built.

Sandy Copeman, Director of Brand at Amalgam, said “the Ferrari Daytona SP3 Engine and Gearbox is one of the most exciting new models we will launch in 2023. It may well be the last of Ferrari’s naturally aspirated power units and we are delighted to be working alongside the design and engineering teams at Ferrari to capture this piece of modern automotive history and deliver it at 1:4 scale.”

Working from CAD data supplied directly by Ferrari, the artisans at Amalgam developed patterns for every visible part of the engine, meticulously scaling down the data to ensure that all the details are accurately reproduced in the model. Moulds were created for the individual parts, with metal, carbon fibre and rubber used to create each piece of this intricate and complex assembly. Many parts are CNC machined. The Daytona SP3 Engine and Gearbox replica necessitated over 3500 hours of development and the resulting prototype only received the approval of the Ferrari designers and engineers once they were fully satisfied with its accuracy of representation. Measuring over 43cm (17in) long and 21 cm (7in) high, each subsequent model will take 325 hours to cast, fit, fettle, paint and assemble.

The Daytona SP3 Engine is not the first engine that Amalgam has replicated. The artisans have previously crafted models of Formula 1 engines for Ferrari and the BMW Williams team during the early 2000s whilst, in more recent years, an edition was created for Bugatti based on the iconic W16 engine that powers the Chiron. “And of course every model we have ever built with an opening engine bay contains an exact replica of its power unit” adds Copeman.

The Ferrari Daytona SP3 Engine and Gearbox replica joins Amalgam’s Icona Series Collection of full car models at 1:8 scale alongside the Monza SP1 and SP2, and the SP3 Daytona. The 1:8 car models measure over 58 cms/23 inches long and like the engine they are crafted from thousands of precisely engineered parts.

Copeman continues “The Ferrari Daytona SP3 is a futuristic interpretation of the classic sport prototipo, celebrating one of Ferrari’s most iconic moments when the 330 P3/4, 330 P4 and 412 P took the chequered flag in positions 1-2-3 side by side at the 24 Hours of Daytona in 1967. It was a moment particularly cherished by Enzo Ferrari himself. We are honoured to be a part of the story.”

1:4 scale models of the Ferrari Daytona SP3 Engine and Gearbox are available at www.amalgamcollection.com.

----------------------------------------------------------------

High resolution images and video can be found here >

EDITORS' NOTES:

MEDIA CONTACTS

PR & Media Enquiries: tom@tomgibsoncommunications.com, T: (201) 476-0322, Mobile: (201) 264-3646

PR & Media Enquiries: pressandmedia@amalgam.com

Director of Brand and Business Development: Sandy Copeman sandy.copeman@amalgam.com

Business and Sales Enquiries: enquiries@amalgam.com

ABOUT AMALGAM COLLECTION AND THEIR HISTORY

- Amalgam are recognised worldwide as makers of the finest hand-made large-scale models. Their work is unique in its attention to detail, with a focus on creating models that truly capture the style and spirit of each car. They have dedicated all their skill and passion to achieving a level of excellence that raises the impact and value of each finished piece to a level far above anything previously created.

- For owners of cars they have already modelled at 1:8 in a limited edition, for which the tooling already exists, they offer a tailormade service, customising a model to perfectly match the specification of the real car.

- For owners of unique very high value cars, Amalgam Collection offer an even bigger 1:5 or 1:4 ‘one-off’ model build from their UK workshops in Bristol, England. They will digitally scan the car wherever it is in the world and take up to a thousand pictures of every detail, allowing them to perfectly and accurately replicate everything at scale. Given the significant number of hours required to develop a unique model the costs are high, so the model is built at a very large scale to maximise the impact and detail, and to deliver the ultimate finished piece.

Amalgam Collection’s design, management and development heart is in England, with extraordinarily skilled and dedicated teams producing the bigger editions in Hungary and China. They are a multinational, multicultural team of crafts-men and women, dedicated to creating the world’s most precise, beautiful and exclusive models. Inspired by the F1 teams and iconic luxury car marques of England and Italy that they serve and partner with, they take huge pride in their mission to perfectly capture the designs, and honour the designers, drivers and creators of the automotive art they love.

Originally a partnership of four talented model-makers formed in 1985, from the start Amalgam created finely tuned models for the most important UK and German designers and architects. Working closely with Norman Foster’s team on the Hong Kong and Shanghai Bank and on the Hong Kong Airport project was a fast, steep learning curve which quickly opened their eyes to subtle aesthetics and refined engineering. Working with such gifted architects their passion and desire to model the very best designs was ignited, which in due course led them to Williams F1 and Adrian Newey who were dominating the F1 championship in 1995, then on to Maranello and to the massively important design heritage of Enzo Ferrari in 1999, and latterly to the works of Pininfarina and Ettore Bugatti.

The seminal performance and luxury car designers of the early to mid-20th century were obsessed with achieving ever higher speeds, lighter and more powerful engines, more streamlined bodies, an impassioned quest that inevitably resulted in elegant and beautiful solutions as a consequence of stretching the supreme excellence of the craftsmanship and engineering to the very limits of what could be achieved at the time.

The companies that today bear these iconic names continue to be inspired, and their creativity is still fuelled, by the extraordinary passion and genius of their founders. Amalgam Collection too find inspiration in the creations of the founders and their companies who continue to design and create automotive artworks.

Recognising the beauty and importance of these designs Amalgam Collection have utterly dedicated their energy and passion to modelling these cars to a level of accuracy, precision and excellence that raises the finished replica to a level far beyond anything previously created. Amalgam have chosen to work at a scale of 1:8 which is widely acknowledged to be the most satisfying scale to comprehend the entirety of a car’s design at a glance, whilst in addition showing the most minute details.

To create perfect scale replicas of modern cars they use original CAD data supplied by the manufacturer and work closely with the design team to perfect their rendition of the interior and exterior finishes.

With regard to classics, in their quest for supreme accuracy and authenticity Amalgam’s team goes to great lengths to locate the best examples of original cars and digitally scans them to capture the precise shape and proportions of every part of the car including the chassis, engine and drive train. In addition, 600 to 800 photographs of every aspect and detail of each car are shot, to ensure a complete understanding of the finishes and detailing. The resulting models beautifully and precisely capture the entirety of the original and are impossible to discern from a real car in photographs.

Amalgam is the only maker of model cars in the world that can be considered alongside a maker of luxury watches like Richard Mille or Hublot. In fact, Richard Mille is an Amalgam patron who recognising a shared passion for engineering detail and perfection has commissioned from Amalgam Collection many unique models of his own cars and those he sponsors.

HOW THE MODELS ARE CREATED

- The patterns are created using original CAD from the manufacturer, or extraordinarily accurate digital scans and hundreds of photographs of an original classic car.

- The patterns are used to create silicon rubber moulds that capture every detail.

- Prototyping resin is used to cast the parts from the silicon moulds. Around 20 to 30 parts can be cast from each mould and then a new one must be made.

- Each model is built from thousands of parts: castings, photo-etchings and CNC machined metal components.

- Genuine car paints and manufacturer or archive colour references are used to spray the bodywork.

- It takes between 2,500 and 4,500 hours to develop the tooling for each model.

- It takes between 250 and 450 hours to cast, fit, fettle, paint and build each model.

Every Amalgam Fine Model Car is made entirely by hand from thousands of parts. Detailed original CAD data is supplied by the car's manufacturer or the race team of the car to be modelled. The process of developing each model and creating the master patterns takes between 2,500 and 4,500 hours of skilled work depending on the complexity of the car, with classic cars taking the longest.

In the case of the classic cars an extremely accurate digital scan is made of the car, and hundreds of photographs of all the details of a carefully selected original car are taken, to ensure complete accuracy and adherence to the authentic finishes and materials. Many parts of the model are machined from metal with the major components hand cast from prototyping resin. Each model is individually assembled by a small team of highly skilled model-makers. In total the time taken to machine, cast, hand fettle, paint, polish and assemble each model is between 250 and 450 hours of highly skilled work depending on the complexity of the car.

The finished model is a very precise scale replica of the original car with every detail perfectly and authentically represented at an 8th of the original size. This is modelling elevated to such a high level that it becomes an art form.

Since 1995 Amalgam have been admired and hugely respected by leading designers and engineers in the European automotive industry, as well as F1 designers, drivers and team principals. Amalgam's models appear on the desks of CEOs and presidents of the world's most important car companies. Due to the extreme accuracy and authenticity of Amalgam's creations, made in small limited editions, they are also much sought after by devoted collectors of fine handmade objects across Europe and in the USA.

SCALE GUIDE